The Role of IoT in Pharma Manufacturing & Distribution

Pharma is placed to reap the benefits that come from the use of IoT app development technologies. Between manufacturing facilities and delivery routes, supply chains and of course individuals who suffer from the disease, there’s numerous sources of data available and a growing array of devices to make use of. Patients, pharmaceutical companies , and supply chain operators can benefit from embracing the IoT at a higher level. Here’s why.

IoT in Pharmaceutical Distribution & Manufacturing

For best results with IoT in Pharma, it is advisable to take expert assistance from a top IoT App Development Company and hire IoT app developers.

1. Supply Chain Management in Pharma

After the drugs have left the manufacturing facility and are transported to different methods of transportation and may be exposed to fluctuating temperature and climate conditions. While in the majority of cases, the care taken is to keep the drugs within the recommended temperatures, the possibility of variations in transit can’t be totally eliminated.

Further, IoT can be useful in these situations, providing the manufacturers with real-time information and better visibility of the supply chain. Temperature changes, or any damage to the product will be immediately reported to the manufacturer to decide if the product is safe to sell or not.

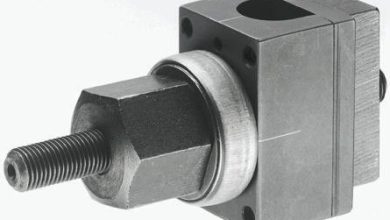

2. Predictive Equipment Maintenance

Individuals working in an industry that is risk-averse such as pharmaceuticals need to prevent the possibility of asset failure at all costs. Quality control has an immediate effect on the health & safety of the consumers. However, there are other issues also, like the long-term durability of machines.

There are a variety of issues that could occur in manufacturing facilities like excessive voltage wear and tear, damaging equipment by impact corrosion or deterioration caused by chemicals or leaks, & much more.

Making sure that consumers are safe as well as increasing the life of machines are two reasons why pharmaceutical companies make the switch to IoT. Also, with onboard sensors and digital dashboards for maintenance, businesses have the ability to get deep insight into the health of their machines. How efficient they are as well as identify and correct problems before forcing a shut down and keep their customers secure.

What types of equipment used in pharmaceutical manufacturing and handling could benefit from preventive & proactive maintenance? The list is here below:

- Material handling equipment

- Sterilization equipment

- Pressure gauges

- Air compressors

- Probes for acidity & temperature

- Vacuum equipment & pumps

There are many advantages of moving towards more proactive approaches to machine maintenance. One of them is that it eliminates the possibility of unexpected downtime. It also allows you to plan maintenance services during operating hours.

Monitoring individual components and machines to check for wear and tear aids in getting the most possible lifespan from their equipment. It may be obvious however the consequences of failures in the health of machines efficiency, performance, and defects can be severe in this field.

Also, medicine capsules that contain mis-doses or medical equipment with inadequate or unsafe quality standards are only two possible outcomes of not making use of operational data to build an automated maintenance system. Recalling a drug or medical device, or prosthetic could reach hundreds of millions without a lawsuit or settlements.

3. Controlling the Drug Manufacturing Environment

Environmental conditions that are not optimal can result in the death of manufacturing drugs. Fortunately, you can manage them by using IoT. Moreover, pharma IoT app development company can bring in the transparency of drug manufacturing and storage environments. Through the use of multiple sensors that keep track of in real-time various indicators in the environment, including:

- Temperature

- Light

- Humidity

- Radiation

All of the information collected is continuously refreshed on a dashboard. Which allows the lab manager to have a quick overview and make the appropriate decisions when needed. After integrating it with an HVAC system, you can use the data to cause automatic adjustments. During a disaster like leakage of toxic substances, the system connected will notify personnel to ensure prompt evacuation.

4. Industry Mechanics & Maintenance

While the utilization of industrial monitoring devices is already commonplace in the pharmaceutical sector, real-time information about status is not yet readily available. Furthermore, utilizing pharma IoT monitoring devices, businesses can instantly transfer all pertinent facility information into a single dashboard. They will alert the supervisor of unusual circumstances or urgent maintenance needs. You can use IoT manufacturing of pharmaceuticals to manage critical situations remotely.

5. Developing Effective Treatments

There are two major areas in which the IoT app development offers new tools to patients’ treatment:

- Firstly, the development of customized medications that target individual patients, the physiology & their condition.

- Secondly, the implementation of patient monitors and wearables to send out automatic notifications to caregivers and reminders. This helps in taking medication and the ability to check in remotely with medical professionals, nurses & doctors.

Last Say

With the lack of transparency, the pharmaceutical industry might not be able to ensure an appropriate and secure development of medicines and distribution. This could lead to a myriad of negative results, including revenues lost, drugs being discarded and even mistreatment of patients.

The main issue the pharmaceutical industry must tackle is how they can gain more control over their operations inside and outside their facilities to remain competitive. Moreover, maximize the time to market & avoid delays in shipping and decrease the amount of waste. All while developing their products and helping larger patient groups by achieving greater effectiveness.

This is a huge challenge to conquer, obviously. But the new IoT app development technology that provides high-speed connectivity is set to give pharmaceutical companies the necessary tools to meet market demands. Hire IoT app developers to integrate the people, the environment equipment, machines, and supply chains together into one system that improves safety, agility & cost-efficiency of the pharma industry.

Also Visit :

5 best Instagram followers apps

Author’s Bio

Harry Miller is an expert app developer at MobileCoderz, an established IoT App Development Company. With 10 years of professional expertise, he/she has worked with rising startups and big enterprises. Aside from the profession, he/she loves to watch romantic movies & write mystery novels.